(주)에스켐텍

Micronized Silica (SS-SIL)

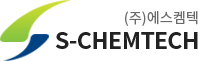

01 Manufacturing process

Silica hydrogel as a raw material of SS-SIL is composed by following mixing reaction between strictly selected sodium silicate and sulfuric acid.

Na₂Oㆍ3.4SiO₂ + H2SO₄ → Na₂SO₄ + 3.4SiO₂

Once silica gel manufactured by above reaction follows washing and drying process to get

desirable physical properties. Next by grinding it, make a variety of SS-SIL grades with

controlling particle size and shape, coherence among particles and filling structure of

particles. The applications of SS-SIL are not only film, paint, ink, paper industries but

also tooth paste, medicine, food industries because it's not harmful to human body.

02 Matting agent for paint, ink

- No haze formation.

- Good transparency property.

- Easy disperse.

- No effect on drying characteristics.

- No effect on intercoat adhesion.

- Excellent scratch and impact resistance.

- high flexibility

Advantage of SS-SIL for paint industry

We are producing various grades of SS-SIL as a matting agent and ceaselessly developing new products to satisfy customer's desire.

03 Anti-blocking and processing aids for PLASTIC

- Excellent dispersiblity.

- Reproducible product quality.

- Stopping the blocking effect of polymer film.

- A beautiful finish to film, sheet and extrudes.

- Giving molds the release they need.

Advantage of SS-SIL in plastic

The properties of Micronized Silica as an anti-blocking agent are maintaining transparency with the same refractive index of film and not being condensed between silica in film. Selecting anti-blocking agent for plastic film is very important because it has great effect on manufacturing condition and quality level of the film.

04 Processing aid for PAPER

- Thermosensitive paper.

- Ink jet recording paper.

- Diazo photosensitive paper.

- Tracing paper.

- Electrostatic for recording paper.

- Multi purpose paper.

SS-SIL as a filler or processing aids for papers is available in grades with different

properties in the following recording papers

Thermosensitive recording paper is widely used in facsimile machines, printers and labels due to its high reliability,

simplicity and high speed. Thermosensitive paper consists of a thermosensitive coloring layer coated onto a base

paper to a thickness of several microns. This layer develops a color when it is heated by a thermal head or a thermal

pen, and thus permits recordings to be made. Mixing SS-SIL with thermal colorants offers the following advantages.

1. A pure white thermosensitive paper is obtained and there is no soiling of the undercoat

2. Smudge adhesion and sticking are effectively prevented.

3. Excellent coloring properties are obtained.

05 Other applications

Filtering agent

SS-SIL has great influence on manufacturing pure drink by filtering protein in it. SS-SIL is not harmful to human body because it is highly refined and has excellent adsorptive powder owing to plenty of minute pores strictly controlled. By controlling moisture contents it prevents dusts on working.Application : beverages (beer, drink), food, edible oil.

Moisture remover/ coagulation preventer

If moisture exists in zinc paint for or alumina paint, hydrogen gas occurs and it makes crack. Micronized powder makes heterogeneous color distribution owing to moisture during storage, transport and handling. SS-SIL has great adsorptive powder thus when added to power-type products, moisture is easily removed. Also it's not harmful to human body, SS-SIL makes it possible to take food custody for a long time when used as a food additive. Application : instant food, powder-type food (salt, sugar), animal food.

Powder additives

SS-SIL can store liquid additive, perfume or effective component because it's not harmful, has lots of minute pores and microscopic particle size. Also these components can be changed to powder-type and quantitative input is easily controlled Application : tooth pastes, medicines, foods, chemicals, etc.

Dentifrice

SS-SIL is used as functional material tooth paste because it's high purity micronized powder which is chemically stable. Comparing to normal precipitation silica it has high purity and low bulk density thus additive efficiency is excellentApplication : tooth pastes, medicines.

주소 : 경기도 안산시 단원구 해봉로 101

Tel : 031-492-4951 | Fax : 031-492-4954 | E-mail : sale@shsilicate.com

Copyright ⓒ (주)에스켐텍 All rights reserved.