(주)에스켐텍

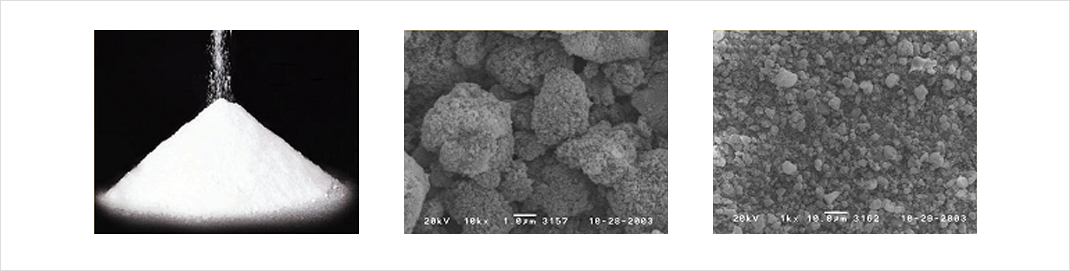

Micronized Sillica (SS-SIL)

When acid is added to sodium silicate, silica sol with primary particle is created.

Raclical dehydration condensation reaction is promoted at silano(Si-OH) on the surface of primany particle by continuous

adding of acid. As a result, network (Si-O-Si) is formed and three dimensional structure is generated. This is so called

Silica gel. Physical properties are controlled via washing and drying processes and finally Micronized silica is produced

by grinding it. Micronized silica has various special propertie by porosity and paricle size distribution, and it is applied

widely in various fields using the characteristics.

Product

General Application

-

Matting agent for Paint, Ink

- SS-SIL as a matting agent is applied to lacquer, polyurethane, epoxy, alkyd, metalic paint and inks. -

Anti-blocking and processing aids for Plastic

- SS-SIL as an anti-blocking agent is applied to various kinds of plastic film such as PE, PP, PET, Nylon and etc. -

Processing aid for Paper industry

- SS-SIL as a filler or processing aids for papers is available in grades with different properties. -

Other applications

- Filtering agent : SS-SIL has great influence on manufacturing pure drink by filtering protein in beverages, food, edible oil.

- Moisture remover / coagulation preventer : Instant food, Powder type food (salt, sugar), animal feed.

- Dentifrice, polishing agent : Tooth pastes, medicines.

대표자 : 홍광표, 양철권 | 사업자 등록번호:134-81-33502

주소 : 경기도 안산시 단원구 해봉로 101

Tel : 031-492-4951 | Fax : 031-492-4954 | E-mail : sale@shsilicate.com

주소 : 경기도 안산시 단원구 해봉로 101

Tel : 031-492-4951 | Fax : 031-492-4954 | E-mail : sale@shsilicate.com

Copyright ⓒ (주)에스켐텍 All rights reserved.